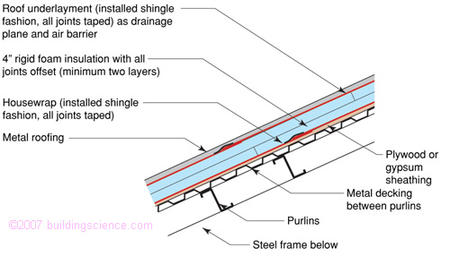

But a purlin is applied directly onto the roof rafters running perpendicular between them while a batten is nailed to roof sheathing or applied over an existing roof for installation of a new roof.

Roof purlin air gap.

Numbers 20 and 22 u s.

Lay the first purlin at the ridge of the roof down to the chalk line beginning at either corner.

Snap a chalk line horizontally across the roof two feet down from the top.

Load tables specifying safe loads for different spans are available from metal deck manufacturers.

Purlins at a 45 degree angle still provide sufficient support for installation of the metal roof panels.

Insert two equally spaced nails into the rafter.

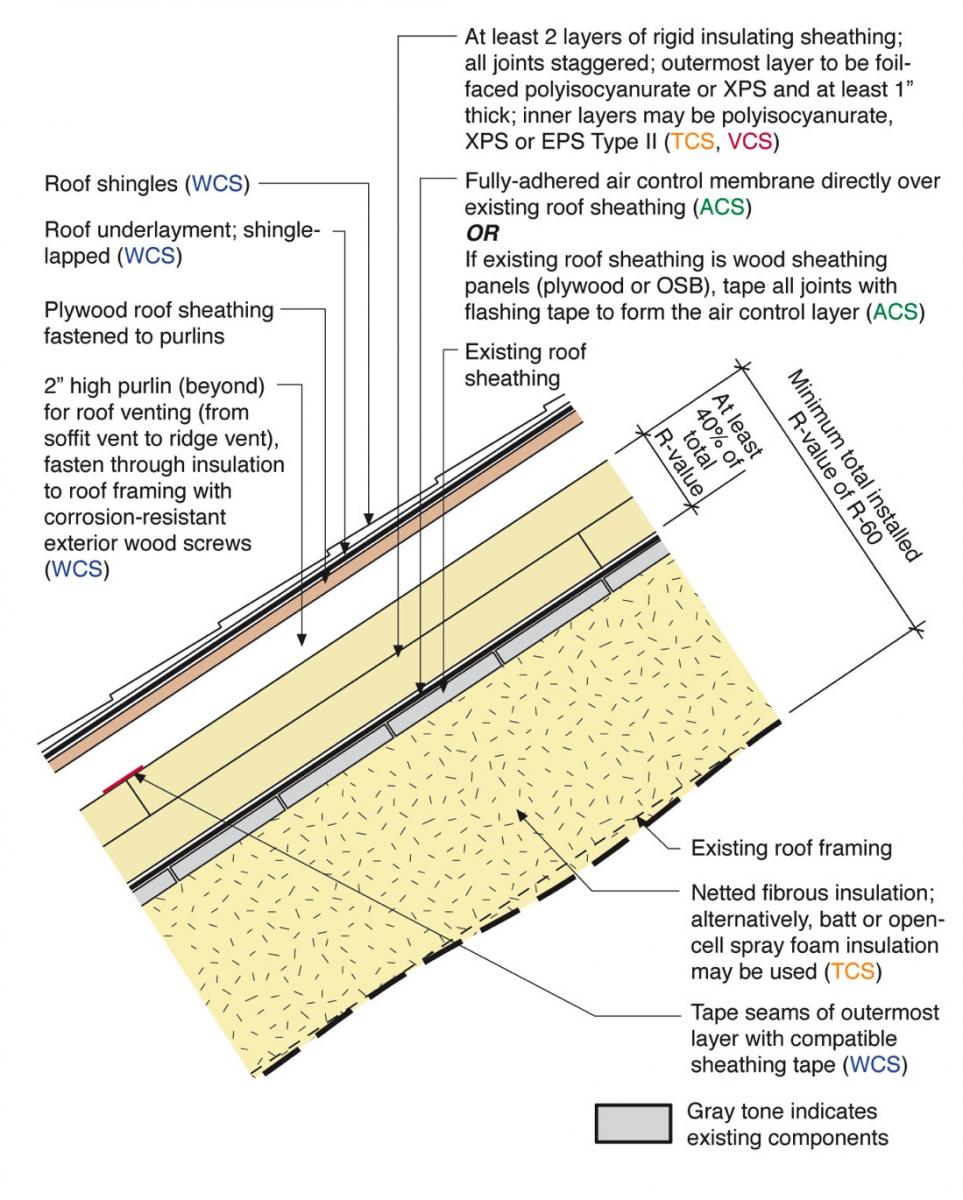

Placing batts between purlins is probably not a top twenty best answer for several reasons.

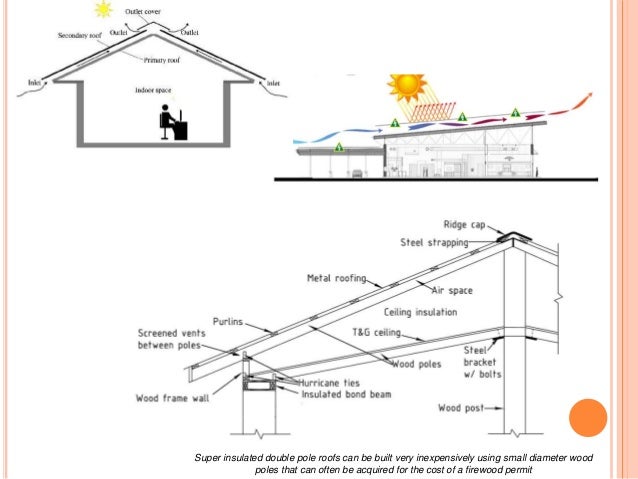

Rising along the underside of the angled purlin until it reaches a gap then rising up to the next purlin and so on to exit at the ridge or gable.

Standard gage are generally used for roofing.

Fasten the purlin with 16d common nails into each vertical rafter.

As the metal roof heats up in the summer time the added air gap in between will act as a buffer instead of the the metal heating up the below shingle roof.

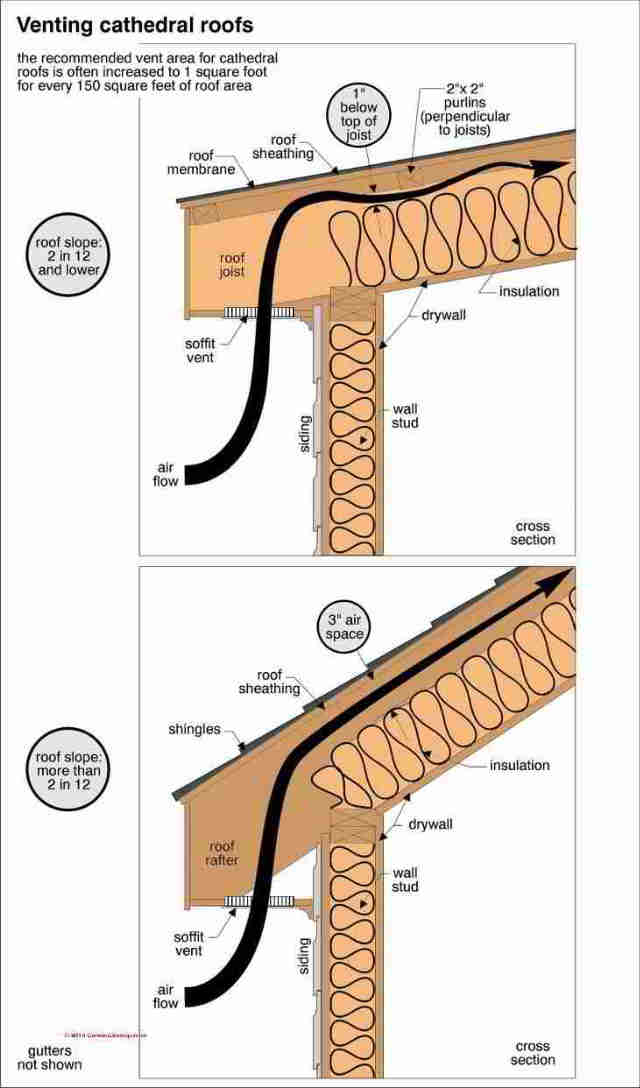

If you do not completely fill purlin cavities code requires airflow from eave to ridge over top of the insulation.

But probably the best benefit that comes from using purlins is the air gap it creates between the metal roof and the existing shingle roof.

The spacing of purlins on roofs and girts on wall is usually 4 to 6 ft.

The photo above shows battens at a tile roof installation in progress.

Ventilation air follows exactly the opposite path.