Alternative roof blocking since most roof damage from high velocity winds occurs at the perimeter edge a metal blocking system has been developed to enhance the roof s perimeter for wind uplift resistance.

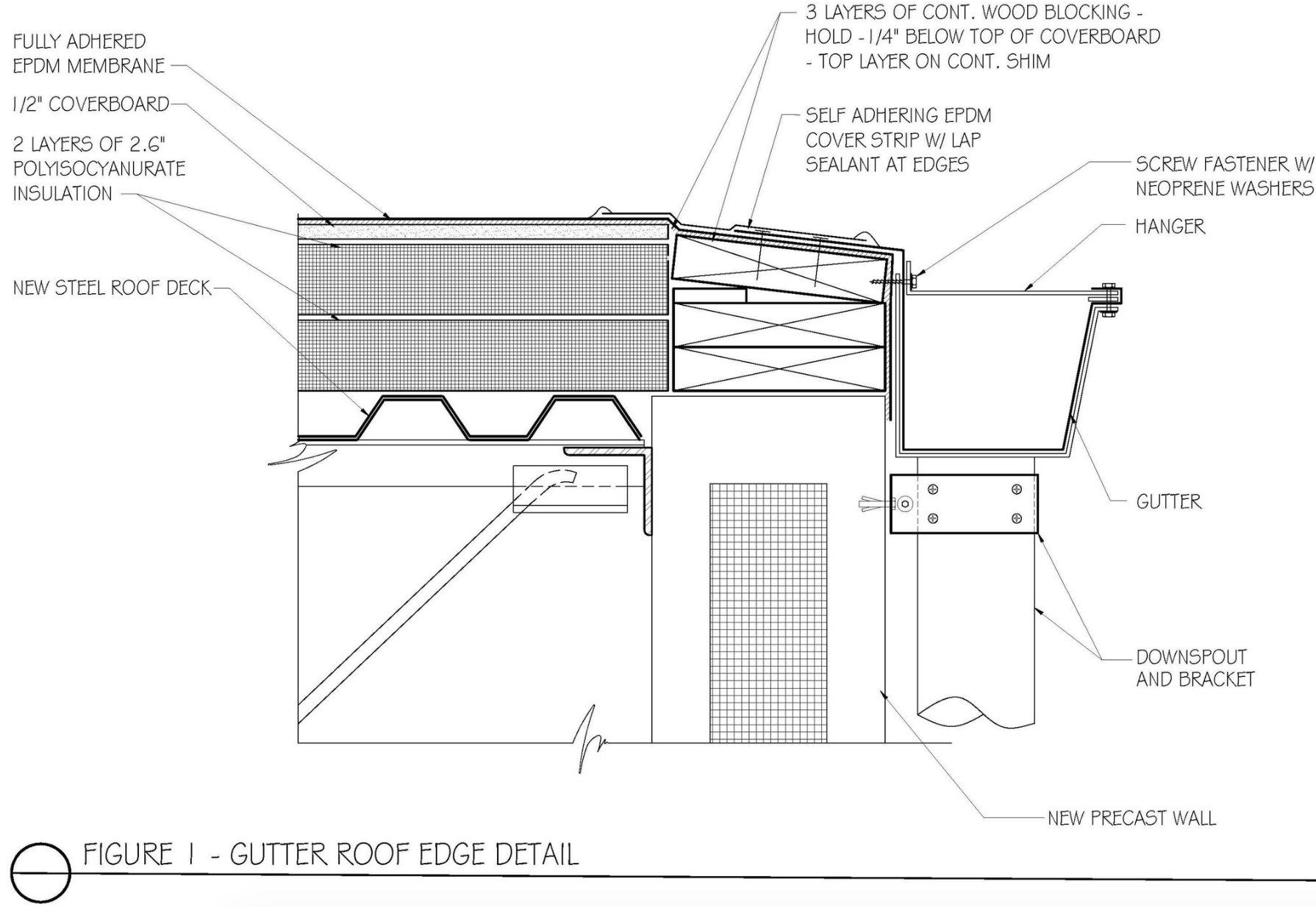

Roof edge blocking epdm.

When the trim is in place it s simply fixed with stainless steel plastic topped pins.

Epdm installation for ballasted and inverted systems a firestone drain bar profile may be used to prevent the gravel from blowing off the roof.

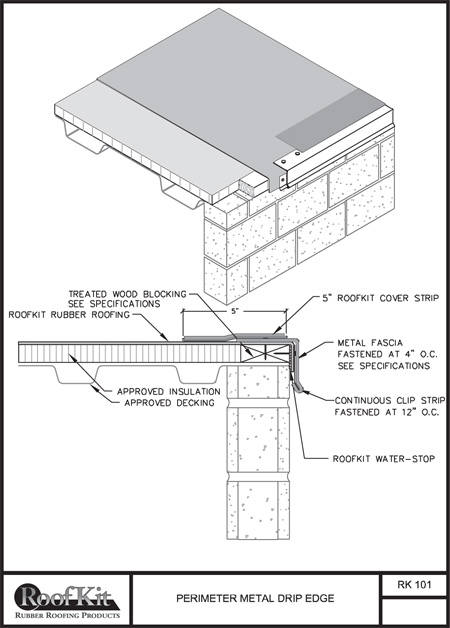

When the entire roof membrane consists of a highly flexible roof membrane such as epdm rubber the membrane itself is turned down the outside edge of the wood blocking.

Ps 1 a option 1 2.

After several annoying years and seeing the epdm begin to lift at roof edges our solution was to cut back 12 of roofing from the lower roof edges remove the gravel guard install the proper flat roof drip edge then glue down a new length of epdm along the roof edge and atop the upper portion of the drip edge.

Kerb edge trims the plastic versions sit on either a bead of mastic sold by manufacturers or foam tape which is compressed between the underneath of the trim and the top of the epdm to form a water tight barrier.

Pressure differences notice the large pressures at roof perimeters.

Universal details video for metal edge terminations.

The alternative roof blocking system arbs is an engineered metal fabrication system that was developed and patented by henry gembala.

Fasten the drain bar at 150 mm centres.

From leutheusser and the department of mechanical engineering university of toronto 1964.

Use 40 mm stainless steel fasteners with rubber washers.

Some of us recall that 1964 was a good year.

Make sure that the top edge of the drain bar extends a minimum of 50 mm above the level of the field membrane.

The rubbergard max epdm membrane is an internally reinforced cured single ply roofing membrane that is designed to combat roof tears and punctures and provides superior resistance to wind forces.

Epdm can be installed either fully adhered mechanically attached or ballasted with the seams of the roofing system sealed with liquid adhesives or specially formulated tape.

But then often the failure is due to an adhesive failure between the metal and the epdm sheet.

Roof edge wind effects when wind blows against a building it produces vortices at the roof edges.